Bucket Elevators Conveyor

Our Services

- Conveying Systems

- Storage Systems

- Weighing Systems

- Batching Systems

- Bagging Systems

- Manufacturing Systems

- Bulk Bag Discharge Systems

- Online Sieving System

- Turnkey Solutions For Process Automation

- Annual Maintenance Contract For Equipment Supplied

Inquiry Form

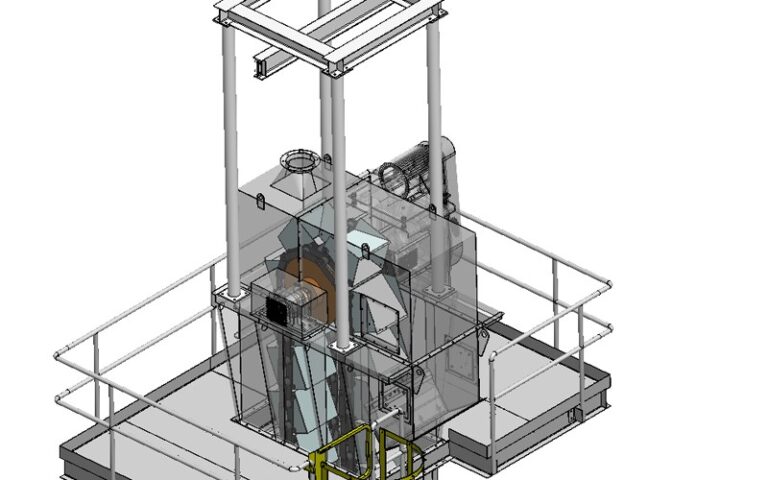

Bucket Elevator Conveyor

A bucket elevator can efficiently elevate a variety of bulk materials in India, from light to heavy and from fine to large lumps. Among the types available, centrifugal discharge elevators may be either vertical or inclined. Vertical elevators rely solely on centrifugal force to propel the material into the discharge chute, necessitating relatively high operating speeds. In contrast, inclined elevators, with buckets spaced apart or closely set, may position the discharge chute partly under the head pulley. This configuration reduces the reliance on centrifugal force, allowing for lower operating speeds.

Bucket elevator manufacturers in India, like KWS, recognize the efficacy of bucket elevators for vertical material handling. These systems comprise a series of buckets affixed to a belt or chain, with pulleys or sprockets positioned at the top and bottom of the unit. The buckets reside within a casing or housing to contain the material effectively. Bulk materials are loaded into each bucket as it traverses past an inlet point. KWS specializes in designing and manufacturing a diverse range of bucket elevators tailored to the characteristics of the bulk material and specific process requirements in the Indian market.

Features of Bucket Elevators

Custom Engineered For Your Specific Application Wide Range Of Construction Materials – Carbon Steel, Stainless Steel And Abrasion-Resistant Alloys Belt And Chain Type Elevators Available To Meet Your Specific Requirements Screw-Type Or Internal Gravity Take-Ups Available

- Low investment Cost

- It has a wider range of working capacity

Advantages of Bucket Elevators

Designed To Handle A Wide Variety Of Bulk Materials – From Average To Very Free-Flowing Many Different Bucket And Casing Sizes Available For Capacities Up To 15,000 Cubic Feet Per Hour Completely Enclosed For Dust And Weather-Tight Operation Inlet Section Can Be Control Fed Or Flood Loaded With Bulk Materials.

- Vertical Transport: Efficiently moves materials vertically, maximizing space utilization.

- Gentle Handling: Minimizes product degradation, ideal for fragile materials.

- Customizable: Tailored configurations for various materials and capacities.

- High Capacity: Handles large volumes of materials, suitable for high-demand applications.

- Continuous Operation: Provides a constant flow of materials, enhancing productivity.

- Low Maintenance: Simple design with minimal moving parts, reducing maintenance needs.

- Space Saving: Compact footprint, ideal for installations in limited spaces.

- Versatile: Handles a wide range of materials, suitable for diverse industries.

- Dust Control: Equipped with features to minimize dust emissions and spillage.

- Energy Efficient: Incorporates energy-saving features, reducing operating costs.

Bucket Elevator Conveyor Manufacturers

Raman Systems leads the industry as the premier bucket elevator conveyor manufacturers in Mumbai. With a stellar reputation for excellence, they specialize in providing the finest customized turnkey solutions for material handling needs. Offering a comprehensive suite of products including batch conveyors, roller conveyors, screw conveyors, bucket conveyors, and drag chain conveyors, Raman Systems ensures optimal efficiency and reliability for diverse industrial applications. Their commitment to delivering tailored solutions that meet and exceed customer expectations sets them apart as the go-to choice for superior material handling equipment. Trust Raman Systems to elevate your operations with unmatched quality and service.