Bin Activators/ Bin Dischargers

Our Services

- Conveying Systems

- Storage Systems

- Weighing Systems

- Batching Systems

- Bagging Systems

- Manufacturing Systems

- Bulk Bag Discharge Systems

- Online Sieving System

- Turnkey Solutions For Process Automation

- Annual Maintenance Contract For Equipment Supplied

Inquiry Form

Vibrating Bin Discharger Systems Manufacturer

Raman Systems is a trusted manufacturer of vibrating bin discharger systems in Mumbai, offering customized turnkey solutions. Our expertise extends to various conveying systems, including drag chain conveyors, roller conveyors, screw conveyors, bucket conveyors, and silo storage systems, available throughout India. With our advanced technology and reliable solutions, we ensure efficient material handling for your business needs.

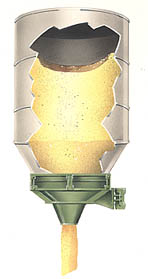

Bin Activators

Vibrating bin discharger systems have been proven to improve the flow of bulk materials from storage, offering an efficient method for discharging dry materials from bins on a first-in, first-out basis with consistent flow. Carrier provides a range of discharging solutions, including vibrating bin dischargers, live bottom bins, vibrating live bins, and storage pile dischargers.

The BA by EXTRAC is the ultimate Bin Activator. Industrially manufactured in large series the BA excels by its seamless cone and its double-flanged, seamless gasket. The BA’s unique design features ensure totally safe operation over time.

Technical Specifications

The BA Bin Activator is a device of tapered conical shape that, due to vibration, facilitates material flow from hoppers or silos. It consists of a seamless carbon or stainless steel cone manufactured on a sheet metal lathe, a seamless SINT engineering polymer seal with integrated upper and lower flange, suspensions for connection with the silo cone, as well as one or two electric OLI motovibrators.

Features of Bin Activators

- Q = 5 ~ 320 m3/h (3 ~ 190 cfm)

- Range: Ø 400mm (16 in) ~ 3,000mm (10 ft)

- Material: carbon steel, 304L / 316L stainless steel

- Robust, compact design

- Range of seals (gaskets) including FDA-approved, food-grade version and high-temperature version

- Wide range of baffle plates in accordance with application

- Low power requirement

- Extra durable suspensions and seal (gasket)

- 70% fewer welds than with traditional bin activators

- Seamless heavy-duty activator cone

Vibrating Bin Discharger Systems

A vibrating bin discharger systems where machine is a conical-shaped device designed to facilitate the continuous flow of dry bulk materials using gravity. It is utilized for feeding downstream equipment like conveyors, hoppers, and rotary feeders connected to its outlet port.

Carman Vibrating Bin Discharger systems eliminate hopper flow problems including bridging and ratholing by using vibratory action to promote bin flow for many materials with challenging flow properties. Individually engineered for each application, the unique design of the Carman Vibrating Bin Discharger allows easy installation with the ruggedness to stay on-line.

Bin Flow Problems

Bridging

A no-flow condition in which the head load of the stored material results in a “bridge” or “arch” formation in the bin or the hopper section of the bin..

Ratholing

A condition in which the stored material does not slough into the central flow stream for discharge and instead forms a core. Problems associated with ratholing include flooding, substantial variation of density in product, and eventually, no-flow.

Carman Bin Discharging Solutions

Eliminate Bridging and Ratholing

The Carman Vibrating Bin Discharger eliminates ratholing by increasing the effective hopper outlet size while the unit’s internal pressure cone eliminates bridging.

Maximize Hopper Volume

With identical elevations and bin diameters, a 60 degree bin with a 5 foot Carman Vibrating Bin Discharger provides 130% more hopper volume than a 70 degree static hopper.