Chemical Batching Systems As Per Process Control

Our Services

- Conveying Systems

- Storage Systems

- Weighing Systems

- Batching Systems

- Bagging Systems

- Manufacturing Systems

- Bulk Bag Discharge Systems

- Online Sieving System

- Turnkey Solutions For Process Automation

- Annual Maintenance Contract For Equipment Supplied

Inquiry Form

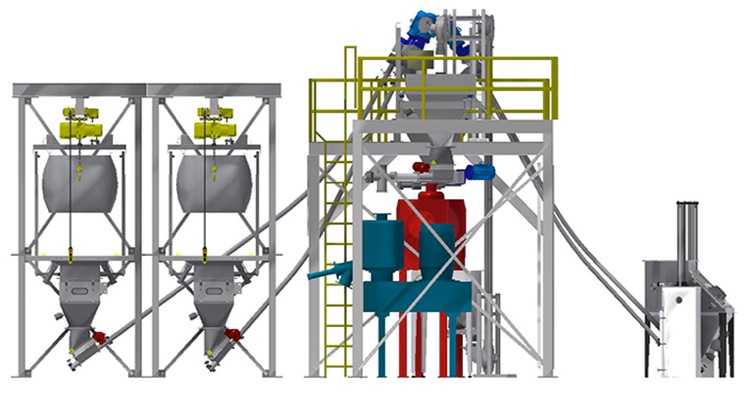

Chemical Batching Systems As Per Process Control

Application Outline

Elonics was tasked to supply and install a control system for a Bulk Chemical Batching Process.We used the LSIS XP-90 HMI as the main operator interface for creating batch recipes and monitoring/controlling the process, we linked the main scale and small parts loadcell system via RS485 to the XEC PLC to control the dispensed weight, once the batch is complete a report is created in LSIS InfoU and printed for the operator.

Application Products Lsis Used

- HMI : XP90TTA/DC

- PLC : XEC-DR64H

- InfoU SCADA

Features

- Totally enclosed, dust-tight and air-tight construction.

- Moves material approximately 8 to 12 feet per minute.

- Has up to a 35 degree incline to storage location and/or disposal location.

Application Benefits

- Create Larger Chemical Batches

- Locally supported products used – LSIS

- More precise weighing/Dispensing

System Requirements

- Batch Recipe Storage and Reporting

- Automatic control

- Precise Weighing

- Reduce Operator Error

- Reliable Solution

Key Functions

- HMI Recipe Function

- InfoU SCADA – Batch Reporting

- Direct Serial Communication with Weighing Scale