Drum Dryers

Our Services

- Conveying Systems

- Storage Systems

- Weighing Systems

- Batching Systems

- Bagging Systems

- Manufacturing Systems

- Bulk Bag Discharge Systems

- Online Sieving System

- Turnkey Solutions For Process Automation

- Annual Maintenance Contract For Equipment Supplied

Inquiry Form

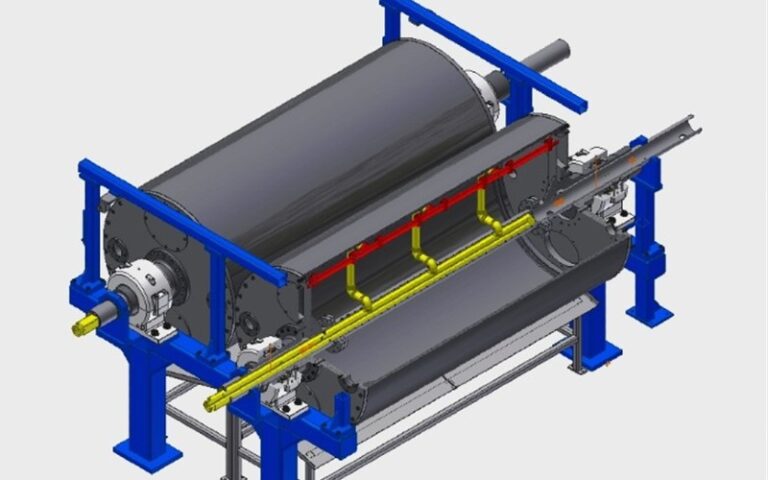

Drum Dryers

Drum drying is a method used for drying out liquids from raw materials with drying drum. In the drum-drying process, pureed raw ingredients are dried at relatively low temperatures over rotating, high-capacity drums that produce sheets of drum-dried product. This product is milled to a finished flake or powder form. Modern drum drying techniques results in dried ingredients which reconstitute immediately and retain much of their original flavour, colour and nutritional value.

Some advantages of drum drying include the ability of drum dryers to dry viscous foods which cannot be easily dried with other methods. Drum dryers can be clean and hygienic and easy to operate and maintain.

Features Of Drum Dryers

Drum dryers at kerone has evolved in last 42years, we have added lots of feature to enhance the performance of drum dryers. Below are few of the features of our drum dryers:

- Uniform drying across the materials, due to uniform application and maintaining uniform pressure across the drum.

- Very much suitable of highly viscous, pasty, slurries type of materials.

- Our drum dryers are suitable drying of heat sensitive materials, because of its shorter drying time.

- Highly adjustable, the components of the drum dryer such as pressure, rotation speed, applicator width and other can be adjusted individually

- Drum dryers offers higher thermal efficiency as compared to other drying systems as the drying takes place due to transfer of heat from within drum to outside drum.

- Kerone’s drum dryers are easy to maintain and clean.

- We build drum dryer with wide range of size and heat transfer to handle wide range of material.

- Drum dryers operates in continuous drying mode.